If you’re in engineering or manufacturing, you’ve likely heard the term PLM software tossed around. But what exactly is PLM software, and why are more companies investing in it?

What Does PLM Software Do?

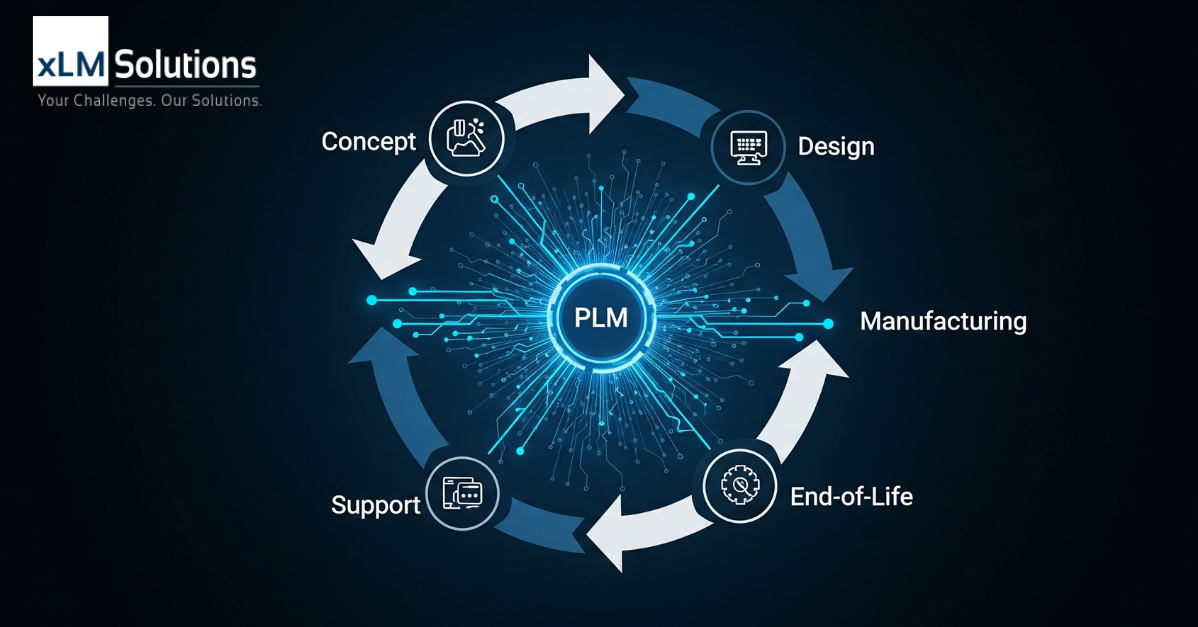

Product Lifecycle Management (PLM) software helps organizations manage every stage of a product’s journey—from initial concept and design through production, service, and retirement. More than just a tool, PLM acts as a single source of truth for product-related data, giving cross-functional teams access to accurate, current information at all times.

PLM systems improve collaboration between engineering, quality, manufacturing, and even supply chain teams. With centralized control of CAD files, Bill of Materials (BOMs), change orders, and documentation, PLM makes it easier to innovate, accelerate time to market, and ensure compliance. Many PLM platforms also support the creation of a digital thread and digital twin, allowing for traceability, simulation, and optimization throughout the entire lifecycle.

Why PLM Is Essential in Today’s Manufacturing Environment

Modern manufacturers are up against tight timelines, complex product designs, and global operations. In this environment, tribal knowledge and siloed spreadsheets don’t cut it.

Without a structured way to manage product data:

- Version control suffers

- Engineering changes are miscommunicated

- Manufacturing builds the wrong revisions

- Quality issues go untraced

PLM addresses these problems by enabling engineering data management, automating change workflows, and providing visibility across teams.

Key Benefits of PLM Software for Engineering Teams

- Manage and control CAD files and product revisions

- Track engineering change requests and approvals

- Link nonconformance issues to product data

- Share accurate, current BOMs with manufacturing

- Improve collaboration across global teams

- Enable digital twins and digital threads for end-to-end product traceability and smarter decision-making

What Are the Top PLM Platforms?

There are several widely used PLM systems on the market. Some of the most popular for manufacturing include:

- Dassault Systèmes 3DEXPERIENCE and ENOVIA – Deep CAD integration and scalable cloud-based collaboration

- Aras Innovator – Flexible, open architecture and strong customization capabilities

- Autodesk Vault and Fusion 360 Manage – Integrated PDM and cloud PLM tools for Autodesk-centric engineering environments

- PTC Windchill – Robust enterprise functionality with strong change management tools

- Siemens Teamcenter – Widely adopted in regulated, global manufacturing environments

Each platform offers different strengths—but software alone isn’t enough.

Successful PLM Starts with the Right Implementation

PLM software can streamline operations and improve product quality—but only when it’s implemented properly. A poor setup can introduce new bottlenecks instead of solving old ones.

At xLM Solutions, we work closely with engineering and IT teams to:

- Integrate PLM with CAD, ERP, and other systems

- Customize workflows to match how teams actually work

- Provide support, training, and guidance throughout adoption

With decades of experience supporting PLM implementations across industries, we understand the technical challenges and the human ones. We don’t just install software—we help your team make it work.

Ready to Explore PLM for Your Organization?

Whether you’re selecting your first PLM solution or trying to get more from an existing system, xLM Solutions is here to help. Get in touch with our team today.