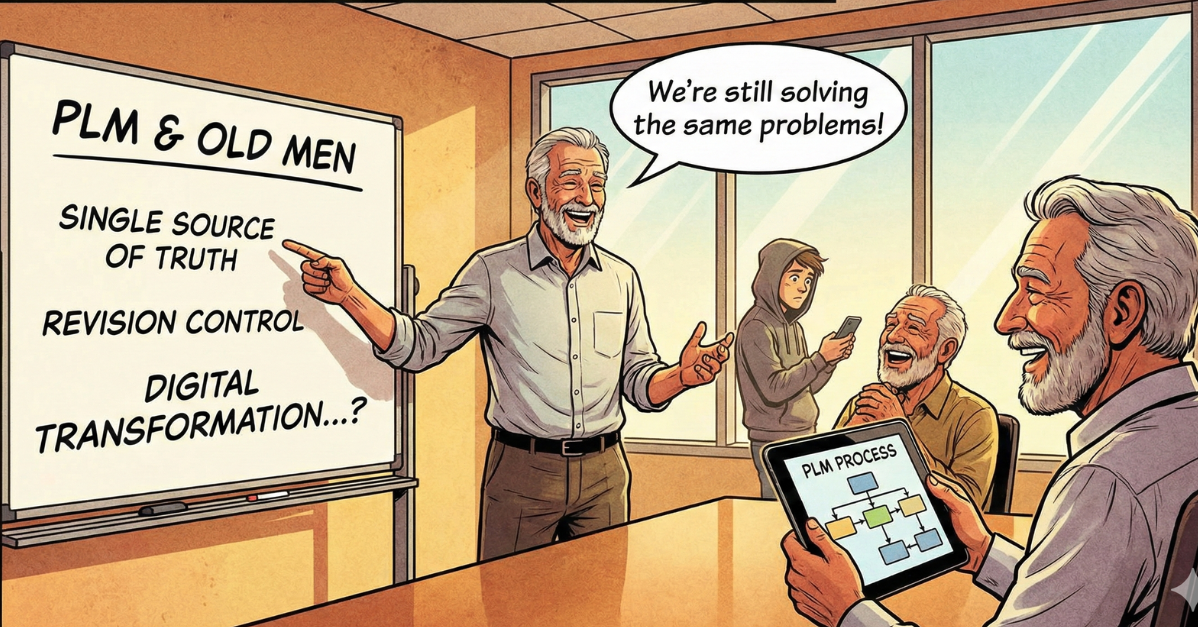

You may think I titled this blog to catch your attention – and, indeed, there may have been some of that at work. However, as you will read below, this is a very important observation, and it’s worth analyzing in the context of the future of PLM.

Who Is Talking About PLM?

As I read through my LinkedIn feed and the blogs of PLM industry experts, I came to realize that everything I am reading is from older males — myself included — who have been working in the “PLM” profession for many years. That’s not to say there are no women out there; shout-out to the ladies at SharePLM and Cheryl Peck. It just so happens that the same PLM geeks who are discussing and writing on this topic, and have been for a very long time, tend to be old men.

Now, I have great respect for these people and consider them my mentors, colleagues, and friends. But I have to admit that at times it feels like they are acting as PLM elites, communicating and posting among themselves like an old boys’ network. I question whether their ideas, articles, and posts are getting to the broader PLM market.

Here are a few examples of recent works that take a more academic view of PLM:

- PLM is dead and must evolve

- Do not refer to PLM as PLM; use other buzzwords: digital transformation, single source of truth, data-centric systems engineering…

- What is the future of PLM? Will PLM exist in the future?

- PLM fails because of blah, blah, blah — companies won’t change, they don’t understand it, it’s too complex, overpromised and underdelivered…

Reimagining PLM vs. Reality

You get the point. Stalwarts want to reimagine PLM by providing new names and introducing glitzy technical terms to show how PLM has “moved on.” But I argue that in the end, it is still PLM. These writers strive to show the newest and greatest, but the core facets of PLM remain, and everything new is based on them.

Yes, some of these are great thought-provoking articles, but they don’t focus on what PLM is actually providing for companies today. And revisiting the old-man theme: where are the young people working in PLM? Am I missing you in my LinkedIn connections? What are your thoughts? Are you supportive of PLM? Why aren’t you out there discussing, challenging, and debating the old guard? We welcome your ideas, your knowledge of the most current developments, and what you learned in school that many of us were never taught.

I have been working in the PLM industry for 25+ years and, to be frank, there really hasn’t been much change in PLM. I am solving the same problems and issues now that I solved when I started my career. And this is not a bad thing. PLM is endemic to industry, incredibly useful, and provides operational efficiencies that were not available prior to its inauguration.

Of course, there have been technical changes, such as:

- Cloud/SaaS solutions

- RESTful APIs and web services

- Modern interfaces

- Faster CPUs, networks, etc.

- More complicated products with mechanical, electrical, and software components

But these changes haven’t replaced PDM; they have made PDM better. The same core principles still strongly apply today as they did 25 years ago.

Let me illustrate. When I began my first PDM training with BaanPDM, I covered topics that are still key today:

- Revision Control — making sure all changes are captured and recorded, and preventing users from stepping on each other’s work.

- Data Access and Security — giving correct access to data and ensuring people can only perform operations they are authorized to do. For example, preventing the shop floor from accessing an older revision of a drawing and building to the wrong rev.

- Searching — the ability to easily find and search for data, then reuse it as appropriate. We can always reference the statistic that an engineer spends 20% of their time looking for data.

- Managing Links and Relationships — especially important when dealing with complex data such as CAD, performing where-used analyses and impact analyses. Having correct data linkage is key for the digital thread (to use a buzzword).

- Managing the Bill of Materials is also a key aspect here.

- Change Management — having an efficient process engine to set up flexible Engineering Changes (Requests, Orders, Notifications, etc.) and to efficiently run and record sign-off information.

Building on the Fundamentals

Once companies get the above basics under control, we can expand PLM into other areas such as configuration management, quality management, requirements management, and program/project management.

The next question making the blog rounds is whether “PLM is only for engineers?” I say No! In many cases, PLM may have initially been brought into a company through the engineering department. However, many companies I work with have expanded PLM usage and exposure throughout the enterprise. While engineering uses PLM to manage CAD, BOMs, and change, I am seeing PLM used enterprise-wide in areas such as:

- Non-engineering departments using PLM to manage their data and documents

- Enterprise access to company data — I have seen PLM on the CEO’s computer so they can access data and run reports

- Shop floor access to released data (drawings, models, MBD) to avoid building to incorrect prints

- Integration to enterprise systems like ERP or MES (data should only be entered once)

- Supplier and vendor collaboration hubs

- Reporting and metrics to provide visibility and KPIs across departments

To sum up, too many of the PLM influencers (us old men) are trying to turn PLM into something it is not. I say PLM can stand on its own. It has staying power, remains an invaluable tool, and maintains its key place starting in engineering while extending its tentacles throughout the organization.

Although PLM has been around for a generation and used primarily as an engineering tool, it has never been — and still is not — easy to implement. A proper PLM implementation takes time and comes with challenges. Companies will need to change processes, manage how users adapt, configure or customize the system, load legacy data, train users, and provide support.

The Realities of PLM Implementation

Implementing PLM requires a good understanding of why it is needed, what problems need to be solved, and the company’s overall goals. It requires an experienced team of experts to configure it properly so it works for the company and performs as intended. This can be achieved via assessments and solution architects designing a solution to meet the company’s specific needs.

Other key aspects include good implementers, executive sponsorship, mid-level management involvement, and commitment to the program. To be candid, this takes time and money to do right.

But keep in mind: when initially introducing PLM to a company, there is no need to start with a complete company transformation — which is overwhelming on many levels. I suggest starting in areas in which we are experts, such as engineering, and then taking a crawl–walk–run approach depending on the company’s culture and goals. Introducing PLM can be broken down into many manageable phases.

When PLM is implemented correctly, companies will see the value and the ROI. From there, it’s a small jump to invest more, expand PLM’s footprint, and realize increased ROI firm-wide.

Writer’s Note: I specifically left AI out of this blog, as that is a topic for another blog.