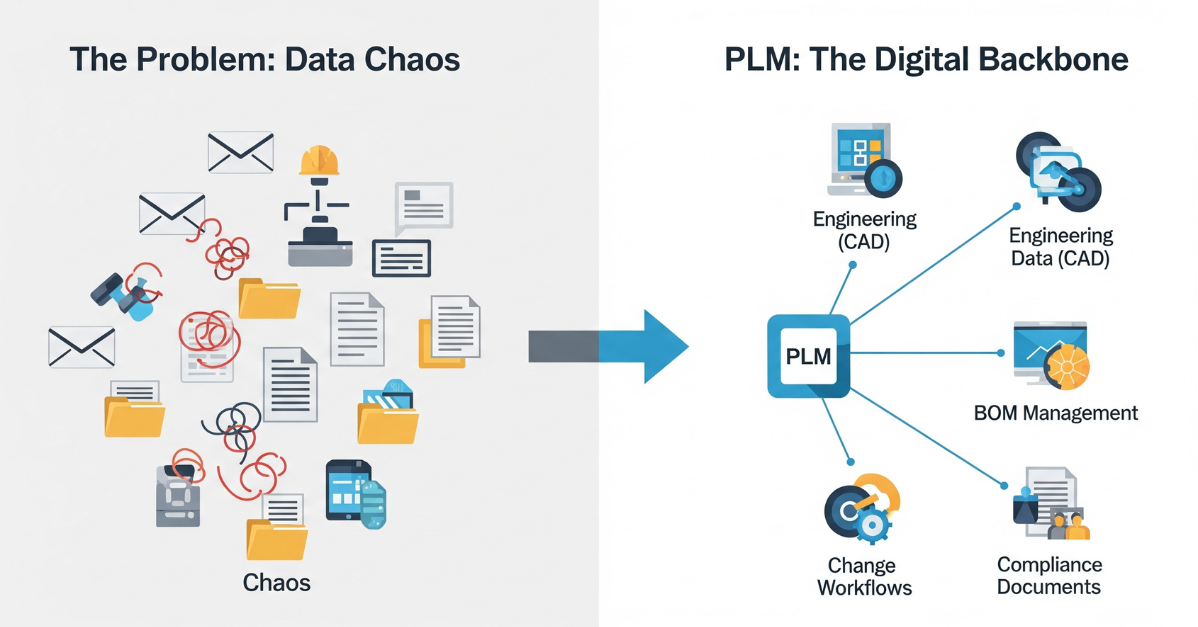

If your team is managing product information with a combination of email, spreadsheets, and shared drives—you’re not alone. But for industrial companies, that patchwork approach often leads to costly errors, long cycle times, and compliance headaches.

Product Lifecycle Management (PLM) systems give industrial manufacturers a structured, scalable way to manage product data and processes from concept through retirement. Whether you’re launching a new line of industrial equipment or supporting complex configurations across regions, PLM helps teams operate with greater speed, control, and collaboration.

What Is Product Lifecycle Management (PLM)?

PLM is both a strategy and a software solution. It enables industrial manufacturers to control the development, production, and service of products across the entire lifecycle.

A PLM system acts as the digital backbone of product operations—linking CAD files, Bills of Materials (BOMs), documentation, and change processes across departments and even global sites.

Core PLM capabilities include:

- Engineering data management (including CAD and drawings)

- Engineering change request (ECR) and change order (ECO) workflows

- BOM version control and structure management

- Compliance documentation and audit trails

- Collaboration across design, quality, and operations teams

For industrial firms managing complex assemblies, regional variants, or strict compliance requirements, PLM is no longer optional—it’s foundational.

Benefits of PLM Systems for Industrial Manufacturers

Industrial companies face unique challenges: long product lifecycles, diverse product lines, multi-site engineering, and increasingly strict regulations. PLM helps address these realities with purpose-built structure and visibility.

Centralized Engineering Data

PLM eliminates scattered file storage and ensures teams work from the latest approved designs. This reduces costly rework and shortens time to release.

Formalized Change Management

Whether you’re managing large capital equipment or fast-turn engineered components, a PLM system gives you traceability and control over every change, including approvals, histories, and notifications.

Cross-Functional Collaboration

Quality, engineering, and manufacturing teams can access shared product data without relying on outdated email chains or offline spreadsheets.

Compliance and Audit Readiness

From ISO to industry-specific standards, PLM helps industrial firms meet documentation and traceability requirements more easily and confidently.

Faster Product Development

With structured workflows and real-time visibility, industrial teams reduce design iteration cycles, accelerate NPI, and improve product quality.

Common PLM Use Cases in Industrial Manufacturing

New Product Introduction (NPI): Manage gated processes, task completion, and data handoffs from engineering to production.

Design Reuse: Identify and leverage existing components to reduce cost and accelerate timelines.

Supplier Collaboration: Share BOMs, specifications, and drawings securely with contract manufacturers and suppliers.

Aftermarket and Service Support: Enable service teams to access accurate product configurations, manuals, and histories.

Compliance Documentation: Create and maintain documentation needed for regulated industries (e.g., energy, transportation, medical devices).

PLM Platforms Used by Industrial Firms

Some of the most widely adopted PLM solutions by industrial companies include:

- Dassault Systèmes 3DEXPERIENCE and ENOVIA – Deep CAD integration and scalable cloud-based collaboration

- Aras Innovator – Configurable and scalable, with strong customization capabilities

- Autodesk Vault and Fusion 360 Manage – Integrated PDM and cloud PLM tools for Autodesk-centric engineering environments

Each platform has strengths; the right fit depends on your CAD environment, product complexity, and integration needs.

Getting the Most from Your PLM Investment

At xLM Solutions, we’ve helped industrial manufacturers—from mid-sized OEMs to multi-site enterprises—get measurable value from PLM. We understand that tools alone aren’t enough. You need a solution that fits the way your teams work.

We support:

- PLM implementation, integration, customization and data migration

- Custom workflow development

- Data migration from legacy systems

- User adoption and ongoing support

With decades of experience and a hands-on approach, we ensure your PLM system supports your industrial operations, not the other way around.

Let’s Talk About Your PLM Journey

Whether you’re replacing legacy tools, scaling for growth, or struggling to get more from an existing platform, xLM Solutions is here to help.

Contact us to schedule a conversation about your PLM goals.