Nearly every industrial enterprise I speak with is investing in digital transformation. Yet most admit their product data is still fragmented across silos. Design data lives in CAD, manufacturing execution sits in MES, suppliers feed information through spreadsheets or portals, and quality teams rely on their own systems. Even with PLM in place, many companies lack the digital thread required to unify the lifecycle.

The digital thread market is projected to grow from USD 13.83 billion in 2025 to USD 36.81 billion by 2030 (CAGR 21.5%) – and adoption will only continue to accelerate. According to recent industry benchmarks, more than 60% of discrete manufacturers are piloting or scaling digital thread initiatives, and those that succeed report measurable improvements: faster design cycles, stronger compliance, and double-digit reductions in scrap and rework. The lesson is clear: the digital thread is no longer optional.

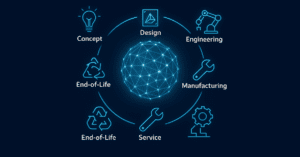

What Is the Digital Thread?

The digital thread is the continuous, contextual flow of data that links every stage of the product lifecycle. It connects concept, design, engineering, manufacturing, quality, service, and even end-of-life. Unlike traditional point-to-point integrations, the digital thread provides a trusted, version-controlled backbone of product information that is accessible across the enterprise.

In practice, this means:

- A design change in CAD automatically informs manufacturing planning.

- Supplier updates flow into engineering change workflows in real time.

- Service data from IoT devices loops back into R&D for product improvement.

- A point of failure can easily be traced back to its source whether design, manufacturing maintenance, etc.

From my perspective, PLM is the backbone of the digital thread. Without PLM governing and contextualizing product data, the thread cannot hold together.

The Digital Twin Connection

The digital twin – a virtual model of a product or process – depends entirely on the digital thread. Without a reliable data backbone, twins are incomplete or inaccurate.

- A twin requires high-fidelity PLM data to stay aligned with reality.

- As products evolve, the twin updates automatically through the digital thread.

- Together, the digital thread and digital twin enable predictive maintenance, faster iteration, and simulation at scale.

The relationship is symbiotic: the thread enables the twin, and the twin demonstrates the business value of the thread. For example, digital thread implementations in shipbuilding have delivered up to 50% time reduction, 30% lower engineering cost, and 50% higher throughput.

Why the Digital Thread Matters in 2025

Leaders aren’t asking what a digital thread is anymore – they want to know why it matters now. In my work with global manufacturers, four themes stand out:

- Agility under pressure: Companies with connected PLM ecosystems were able to adapt to supply chain disruptions 30–40% faster than peers. This is critical considering disruptions like tariffs, rising costs, material shortages and geopolitical constraints have become the new normal.

- Compliance and ESG: Aerospace, defense, and medical device firms are using the digital thread to ensure regulatory traceability and support sustainability reporting.

- Operational savings: Early adopters report 15–25% reductions in errors and rework by ensuring teams work from the same authoritative data.

- Innovation at scale: Continuous feedback loops between design, production, and service accelerate new product introduction and drive competitiveness. Think agile engineering.

Building a Digital Thread Strategy

Despite the hype, I’ve seen too many digital thread programs fail because companies treat them as technology features rather than strategic initiatives. A successful digital thread strategy requires:

- Data migration and cleanup to ensure accuracy and fidelity.

- Integration across PLM, ERP, MES, and quality systems to break down silos.

- Governance frameworks that define data ownership and enforce consistency.

- Change management to ensure teams adopt – and trust – the connected data.

Without these elements, the digital thread becomes a costly pilot with little business value.

Beyond the Enterprise: Connected PLM Ecosystems

In 2025, the most advanced organizations aren’t just building threads within their own four walls – they’re extending them across suppliers, partners, and customers. This is where connected PLM ecosystems come in.

Standards such as STEP, SysML, and emerging regulatory frameworks are enabling interoperability across platforms and organizations. The leaders I work with are investing in architectures where PLM anchors the enterprise thread but also exchanges trusted data across the value chain. That said, I think more standards are needed for PLM data and this is an area we should continue to watch.

This evolution is reshaping industries: automotive OEMs creating modular platforms with suppliers, aerospace primes linking design through maintenance, and life sciences companies enabling traceability from lab to patient.

The Role of AI in the Digital Thread

The next wave is already here: AI-enabled digital threads. Agentic AI systems can:

- Detect anomalies in design or production before they become failures.

- Automate compliance checks across the lifecycle.

- Optimize change workflows and approvals in real time.

At xLM, we are preparing clients for this future by ensuring their data foundation is clean, structured, and ready to support AI adoption. Without high-fidelity PLM data, AI agents have nothing reliable to work with.

Interested in learning how you can create your own AI agent for PLM systems using the emerging MCP (Model-Context-Protocol) standard? In this video, xLM’s Ilan Madjar shows how MCP connects OpenAI, Claude and ChatGPT to 3DEXPERIENCE and SOLIDWORKS PDM to simplify integrations.

Common Pitfalls to Avoid

From experience, I’ve seen three mistakes derail digital thread programs:

- Over-customization of PLM platforms that makes threads brittle.

- Underestimating data governance – without discipline, the thread degrades quickly.

- Treating digital thread as IT-led rather than as an enterprise business initiative.

Avoiding these pitfalls is critical to moving from pilot to scale.

The End Vision

The digital thread is not an endpoint – it’s a foundation. It enables the digital twin, supports agentic AI, and creates the conditions for a future-ready enterprise where every decision is informed by connected, contextualized product data.

This is the direction leading manufacturers are already moving. Those who delay risk falling behind competitors who are building agility, resilience, and innovation on the strength of their digital thread strategies.

How xLM Solutions Helps

Achieving a high-quality working digital twin and thread requires much more than the click of a button. As mentioned, it takes corporate initiative and commitment, as well as strategic and tactical work to bring your systems and data into alignment.

At xLM Solutions, my team and I specialize in helping organizations move from concept to execution with the digital thread. We provide:

- Migration expertise to bring legacy data into high-fidelity modern PLM environments.

- Integration services to connect PLM with ERP, MES, and quality platforms.

- Governance design to ensure threads remain accurate and sustainable.

- Practical adoption strategies to help companies scale beyond pilots.

In my view, the companies that win in the next decade will be those that treat the digital thread not as a buzzword but as the backbone of their digital enterprise.

Are you ready to move from fragmented data to a connected lifecycle? Talk to xLM Solutions about building a digital thread strategy that delivers measurable business value.